According to the EU's implementation of the General Data Protection Regulation (GDPR), we are committed to protecting your personal data and providing you control over your personal information.By clicking "Accept All," you allow us to place cookies to enhance your experience on this website, assist us in analyzing website performance and usage, and enable us to deliver relevant marketing content. You can manage cookie settings below. Clicking "Confirm" means you agree to the current settings.

EQUIPMENT

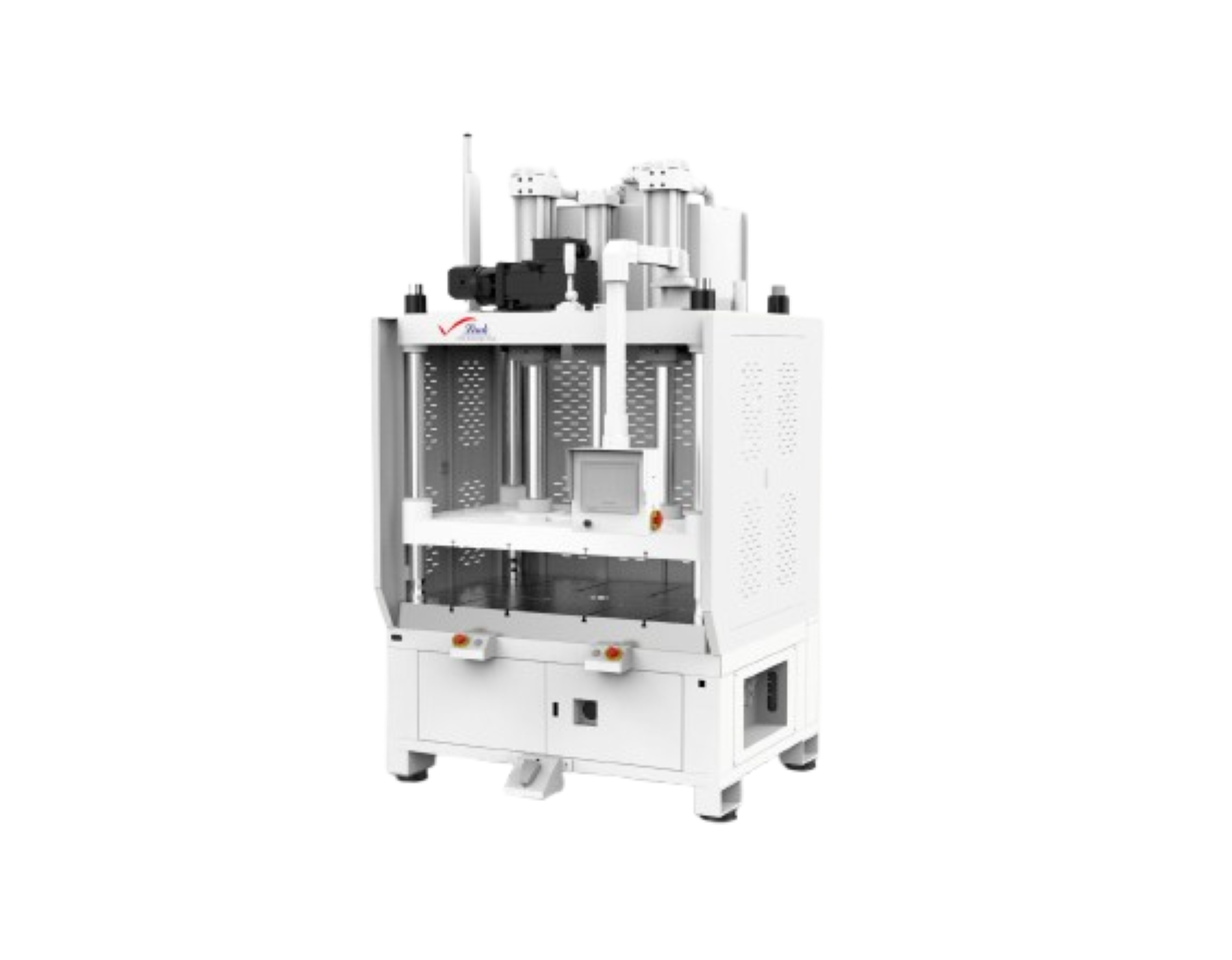

Trimming Machine

Suitable Applications :

Automotive interior parts, white goods shell, notebook computer shell film and other related product shells.

Specifications

| Model and equipment | TM-YJ200 | TM-YJ300 | TM-YJ400 |

|---|---|---|---|

| Clamping force (Tons) | 20 | 30 | 40 |

| Mould opening force (Tons) | 7.5 | 9.5 | 12 |

| Template size (mm) | 1400*950 | 1650*1100 | 2280*1010 |

| Column spacing (mm) | 1200*750 | 1400*800 | 1720*1060 |

| Minimum mold thickness (mm) | 250 | 250 | 250 |

| Mould opening stroke (mm) | 500 | 500 | 750 |

| Maximum mold opening distance (mm) | 750 | 750 | 1000 |

| Maximum hydraulic pressure (Kg/c㎡) | 140 | 140 | 140 |

| Pump output (L/min) | 100 | 126 | 150 |

| Operating oil volume (Liters) | 180 | 200 | 250 |

| Cooling method | Water-cooled | Water-cooled | Water-cooled |

| Motor (kW) | 18.5 | 22 | 30 |

| Industrial control capacity (kW) | 0.7 | 0.7 | 0.7 |

| Average power consumption (kW) | 7 | 7 | 7 |

| Side core (Hydraulic) | 4 Set | 4 Set | 4 Set |

| Side core process | Core insert → Manual (or automatic) vacuum suction → Press mold-closing button → Fast mold closing → Pause at mid-position (predefined stop) → Side core A forward → Side core A retract → Side core B forward → Side core B retract → High-pressure mold closing → Mold opening → Stop suction → Remove product → Repeat cycle | ||

| Machine weight (Kg) | 4000 | 6000 | 12000 |

| Dimensions (mm) | 1600*1600*2850 | 2100*1600*3200 | 28000*180*3800 |